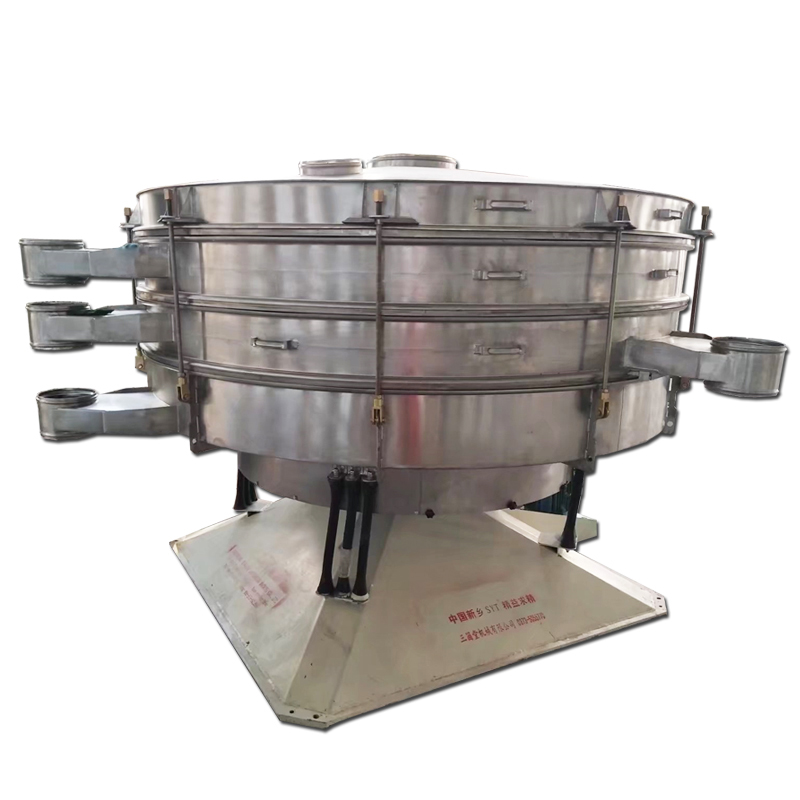

Round tumbler screen introduction

HXSY series of Round Tumbler Screen Machine is a low-frequency rotary vibrating screen which imitates manual sieving. The principle of this model: its instantaneous motion is combination of the radial displacement and the circular motion with the displacement as the axis (spiral motion). The vibration exciter with adjustable eccentricity produces nonlinear three-dimensional movement, and materials also produces the same movement similar to manual operation, so as to achieve purpose of screening. It is suitable for materials with spherical, cylindrical, flaky and even irregular shape, which are easy to block the mesh and need precise screening. In order to meet requirements of customers for large capacity and high precision screening, we specially designed and developed such a kind of high efficiency and high precision screening machine. It effectively simulates principle of manual operation of screening movement, and screens ultra-fine powder and micro particles, which is especially suitable for special materials that are hard to be screened.

With the screening accessories, a more ideal screening effect can be obtained a kind of inertial equipment with mature technology and classical application.

The Tumbler sieve machine is particularly used to classify small materials and fine powder according to its unique structure and working principle. It is not only applied to dry sieving, but also wet sieving. Now this model is widely used in mining, building material, metallurgy, foundry, abrasive material, chemical, light industry, medical, food and other industries..

As its screen and frame are made of different materials and designed by different craftwork, the whole sealing structure prevents materiel dust from moving out without air pollution. On the other hand, it is very easy to add drying, cooling, deducting, cleaning and other supporting facilities as part of the tumbler screen.

.jpg)