Please Check the Parameter of Mill Jar and Mill Ball

| Material |

Volume of Mill Jar |

Diameter of Mill Ball (mm) |

| Stainless Steel |

50ml,100ml,250ml,500ml,1L,1.5L,2L,2.5L,3L,4L |

1-30mm |

| Zirconia |

50ml,100ml,250ml,500ml,1L,1.5L,2L,3L,4L |

1-30mm |

| Alumina |

50ml,100ml,250ml,500ml,1L,1.5L,2L,3L |

1-50mm |

| Tungsten Carbide |

50ml,100ml,250ml,500ml,1L,1.5L |

3-10mm |

| Agate |

50ml,100ml,150ml,250ml,300ml,400ml,500ml,1L,1.5L,2L |

6-35mm |

| Iron Core PU |

\ |

15-30mm |

| Nylon |

50ml,100ml,250ml,500ml,1L,1.5L,2L,2.5L,3L,4L |

\ |

| PU |

50ml,100ml,250ml,500ml,1L,1.5L,2L,2.5L,3L,4L |

\ |

| PTFE |

50ml,100ml,250ml,500ml,1L,1.5L,2L,2.5L,3L,4L |

\ |

We provide all kinds of mill pots in any matched size, which are made from following materials of agate, Alumina corundum ceramics, zirconia ceramics, silicon nitride ceramics, carborundum ceramics, stainless steel, high wear resistant steel, manganese steel, nylon, PU, cemented carbide, crystal glass, and etc.

Available Mill Jars & Specifications

|

Description of Mill Jars

|

Available Specifications

|

|

304 Stainless steel mill jar

|

From 50ml to 25L

|

|

Alumina ceramic (Corundum) mill jar

|

From 50ml to 10L

|

|

Zirconium mill jar

|

From 50ml to 5L

|

|

Nylon mill jar

|

From 50ml to 25L

|

|

Polyurethane mill jar

|

From 50ml to 1L

|

|

PTFE/Teflon mill jar

|

From 50ml to 10L

|

|

Agate mill jar

|

From 50ml to 2L

|

|

Tungsten carbide mill jar

|

From 50ml to 2L

|

|

316l Stainless steel mill jar

|

Customized

|

|

304 Stainless steel vacuum mill jar

|

Customized

|

Matching Solutions Recommendation for Materials & Mill Jars

|

Materials & Requests

|

Recommended Solutions

|

|

Soil materials and other materials which are not

allowed with any impurity contamination

|

Agate mill jar

|

|

Metal or nonmetal which are not allowed

with any impurity contamination

|

Zirconium mill jar

|

|

High hardness materials like diamond, tungsten carbide

|

Tungsten carbide mill jar

|

|

Strong add & alkali materials, or other

materials under high temperature

|

PTFE mill jar

|

|

Iron ore materials or other materials

with low impurity sensitivity

|

304 stainless steel mill jar

|

|

Pigment or materials with later processing under high temperature

|

Nylon mill jar

|

|

Aluminum materials like ceramic glaze

|

Corundum mill jar

|

|

Electronic materials like lithium battery

|

Polyurethane mill jar

|

|

Easily oxidized materials or some materials which need

to be protected under special atmosphere

|

Vacuum mill jar

|

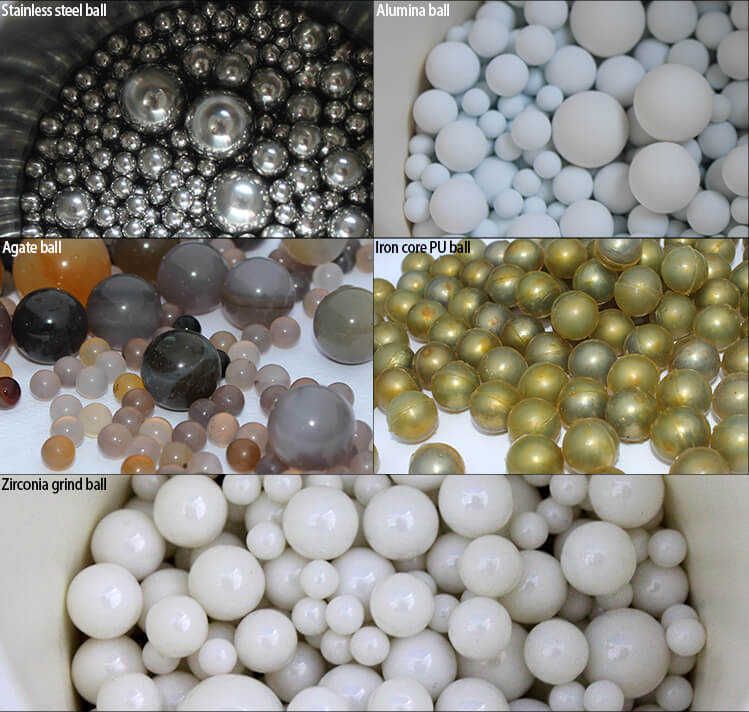

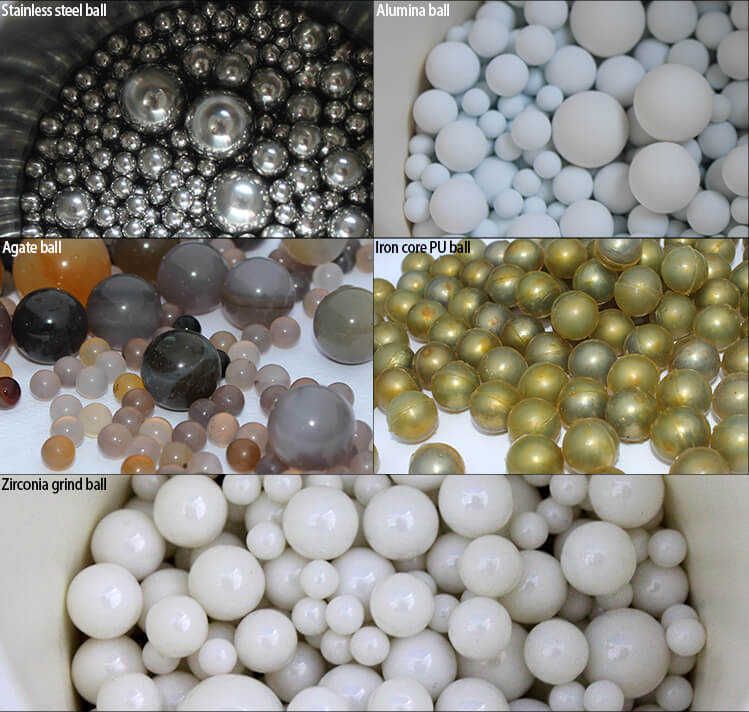

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.

Available Mill Balls & Specifications

|

Descriptions

|

Available Specifications (Diameter Size)

|

|

304 Stainless steel mill balls

|

From 1mm to 30mm

|

|

316l Stainless steel mill balls

|

From 1mm to 30mm

|

|

Alumina mill balls

|

From 1mm-50mm

|

|

Zirconium mill balls

|

From 0.1mm to 30mm

|

|

Agate mill balls

|

From 1mm-30mm

|

|

Tungsten carbide mill balls

|

From 2mm to 20mm

|

|

Carbon steel mill balls

|

From 1mm to 30mm

|

|

Iron core PU mill balls

|

From 15mm-30mm

|

Suggestions for Matching Solution About Grinding Medium & Materials

|

Grinding Balls

|

Hardness

( Mohs )

|

Characteristics

|

|

Tungsten Carbide Balls

|

≥9.0

|

Super wear-resistance, no impurity, anti-corrosion,

High temperature resistance

|

|

Zirconia Balls

|

≥9.0

|

Super wear-resistance, no impurity, anti-corrosion,

High temperature resistance, commonly used for medicine, food and other materials which can not be allowed with impurity.

|

|

Stainless Steel Balls

|

≥6.0

|

Wear-resistance, anti-corrosion, high temperature resistance, brings some impurity.

|

|

Agate Balls

|

≥7.0

|

Super wear-resistance, commonly used for medicine, food and other materials which can not be allowed with impurity, anti-corrosion, high temperature resistance

|

|

Alumina Balls

|

≥8.5

|

Wear-resistance, anti-corrosion, high temperature resistance, brings impurity

|

Pictures of Accessories & Spare Parts

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

01.jpg)

.jpg)

.jpg)

.jpg)

.jpg)