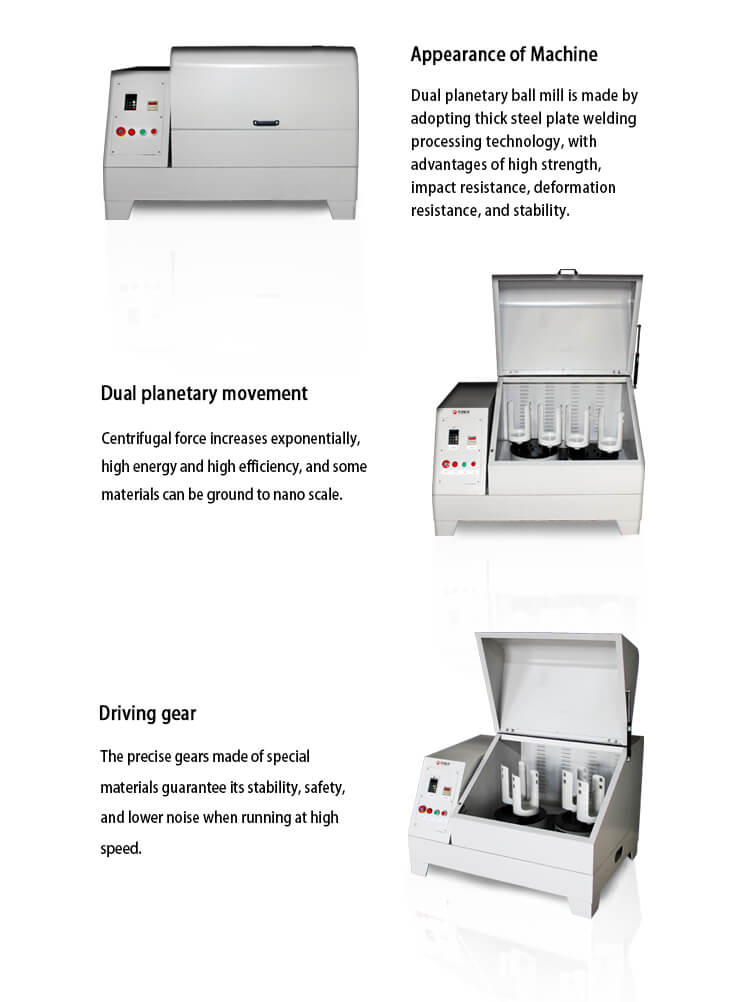

Tencan dual planetary ball mill shell is welded with thick steel plate, which has high strengths, impact resistance, deformation resistance, fine workmanship, strong and beautiful appearance. The material ofmechanic parts is strictly processed by heat treatment process and numerical control processing technology. The gear box is adopted with quasi-sealed groove embedded structure, and the drive gear is made of wear-resistant precision gear. The machine frame and structure are fully considered in design to ensure the stable, safe and reliable operation of the ball mill under long-term and high load conditions, and to effectively achieve the effect of noise reduction in the operation of the machine. The liquid oil self-lubricating device is designed with low noise and high intensity, and it is equipped with a liquid oil level meter for easy replacement. With the touch screen of micro-computer, machine operation is becoming convenient, the interface is more simple and intuitive,forward and reversal alternating control can be achieved easily. It owns functions of timing and power-off memory.

1. The mill pot makes two planetary movement, It enjoys high efficiency and small particle size under the high frequency percussion, linear collision force, friction force.( First in China)

2. Four different samples can be got at one time. It is convenient for the technologist to do the research and develop the new material.

3. Feed Granularity of Materials: Soil material ≤10mm, other materials ≤3mm.

4. Wet or dry grinding method. Minimum Granularity of powder amounts to 0.06 μm.

5. Frequency controlled, you can set the speed as per experiment effect.

6. Large turn disc revolution: 50-400rpm.

Small turn disc revolution: 100-800rpm.

Large planetary axis rotation: 100-800rpm.

Mill pot rotation: 200-1600rpm.

7. The planetary ball mill has timing power off, self-timing forward and inversion function. It can raise the efficiency by choosing one-way, alternately, continuously, time-setting operation.

8. Motor power: 0.4L, 2L, 4L: 0.75KW, 220V, 50Hz; 16L, 20L: 5.5KW, 380V, 50Hz.

9. Our planetary ball mill is functional which has low bary center, stable performance, compact structure, easy operation, reliable safety, low noise, and low wastage.

Advantages of Dual Planetary Ball Mill

It is the ideal facility to acquire samples for research institutes , universities as well as enterprise laboratories (can acquire four samples in one experiment). If mated with vacuum ball milling tanks, it can grind samples in vacuum status. The product is extensively applied to in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc.

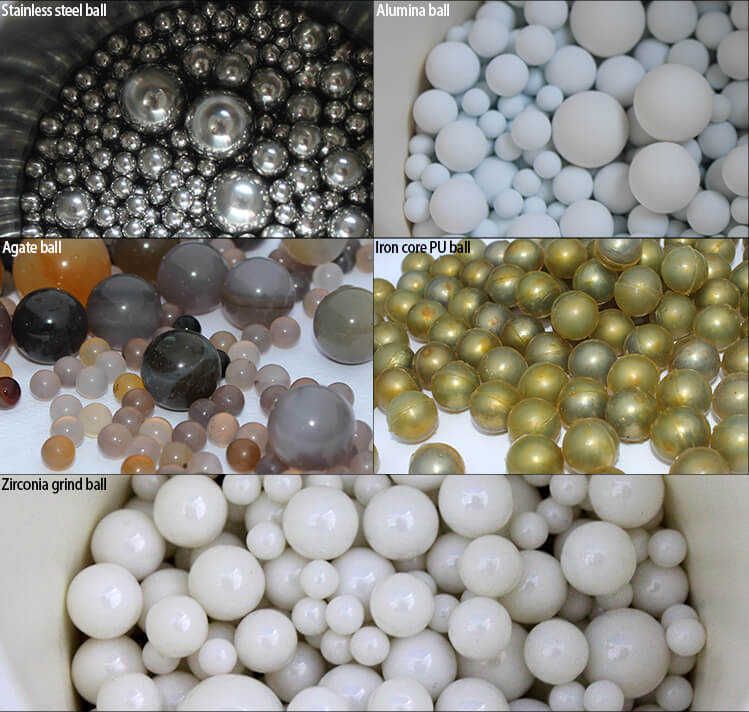

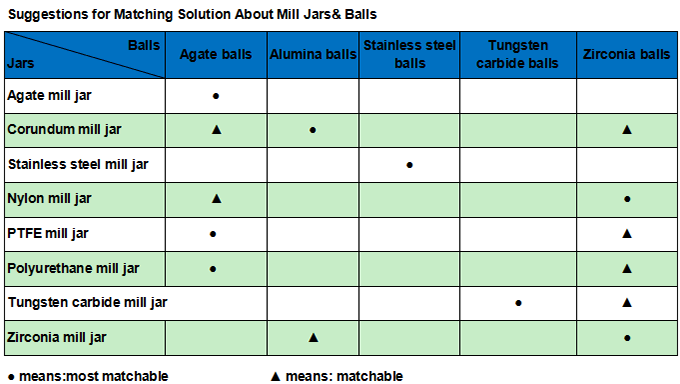

A wide range of powder can be ground by our planetary ball mill with different mill jars and balls, such as ore powder, fluorescent powder, glass powder, pigment powder and so on. Following are some powder samples for your reference.

Applications

SXQM series of dual planetary ball mill is a kind of essential device for laboratory use, which is used for mixing, grinding or producing high-tech new materials in small batch or production. It is widely used in the following industries such as electronic, magnetism, medicine, ceramic, geology, mineral, metallurgy, build material, chemical, light industry, beauty, environmental protection, and etc.

Application Cases of Planetary Ball Mill

.jpg)

Test Report of Grinding Granularity by Planetary Ball Mill

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)